Physical model control on tablet

Physical model control on tablet Physical model with ability calculate future prediction

Physical model with ability calculate future prediction Physical model control product type change

Physical model control product type change MES (Manufacturing execution system)

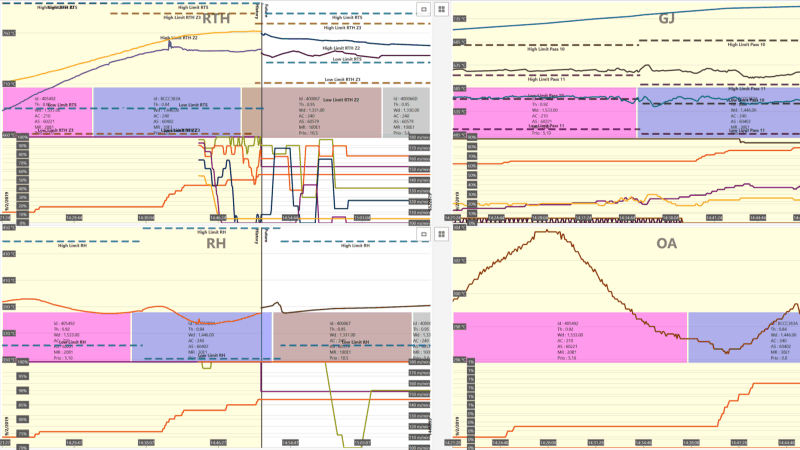

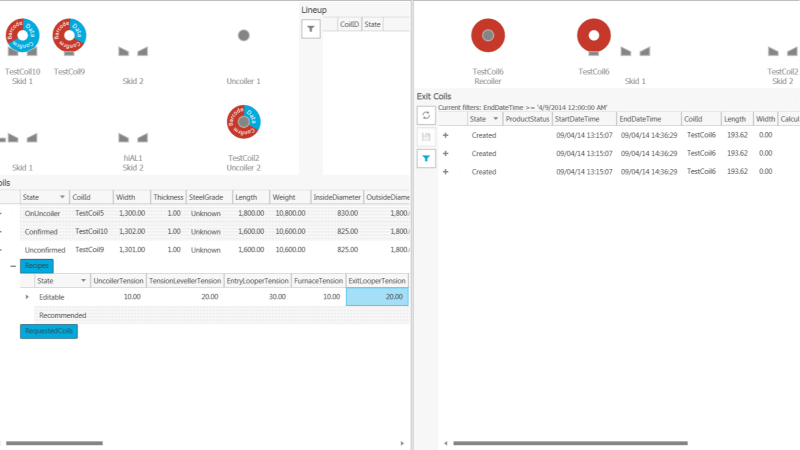

MES (Manufacturing execution system)When production plan is finish we move to phase of real manufacturing. We are able to deliver individual MES (Manufacturing and execution system) which take care data about each producing piece, automatically set new machine settings and parameters individual for each order, collect quality data about production and print out final production report. All these steps are online real-time visible on system.

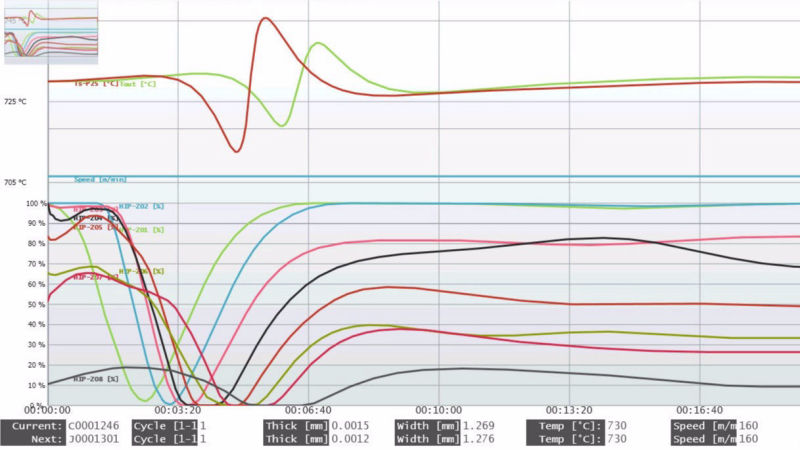

Except MES system we deliver also Mathematical models for your process. These models helps to deliver into machine modified settings based on different sensor measurements. Mathematical model takes your quality target, sensor data and every few seconds modify your machine settings to keep your quality target on high level. This we call real-time manufacturing process control. Again important part of these mathematical models is optimization, which search for best production settings in real-time. The result of such a optimizations must be available in terms of seconds. Mathematical models can have simple form with few parameter calculation up to very sophisticated versions, where is taken into account real physics of manufacturing process (physical models).

Po dokončení výrobního plánu přejdeme do fáze skutečné výroby. Jsme schopni dodat individuální MES (Manufacturing and Execution System), který se stará o data o každém vyráběném kusu, automaticky nastavuje nová nastavení a parametry stroje individuálně pro každou objednávku, shromažďuje údaje o kvalitě výroby a tiskne finální protokol o výrobě. Všechny tyto kroky jsou v systému viditelné online v reálném čase.

Kromě systému MES dodáváme také matematické modely pro váš proces. Tyto modely pomáhají dodávat do stroje upravená nastavení na základě různých měření senzorů. Matematický model vezme váš cíl kvality, data senzorů a každých několik sekund upraví nastavení vašeho stroje tak, aby udržel váš cíl kvality na vysoké úrovni. To nazýváme řízení výrobního procesu v reálném čase. Důležitou součástí těchto matematických modelů je opět optimalizace, která hledá nejlepší nastavení výroby v reálném čase. Výsledek takové optimalizace musí být k dispozici v řádu sekund. Matematické modely mohou mít jednoduchou formu s výpočtem několika parametrů až po velmi propracované verze, kde se bere v úvahu skutečná fyzika výrobního procesu (fyzikální modely).